|

|

| Copper substrate cut into working panel size |

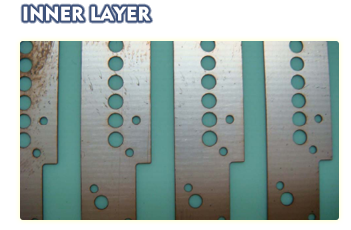

Inner image transfer process

Photoresist (dry film)=>Exposure=>Development=>Etching |

|

|

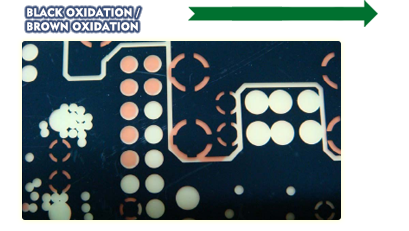

The inner of the copper surface is roughened with

liquid chemicals to increase the prepreg binding force |

Press fit uses high temperatures to make layers of material

Combine |

|

|

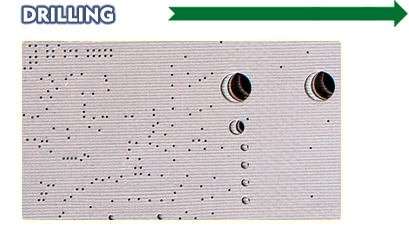

Mechanical drilling uses work files to

drill through layers via positioning |

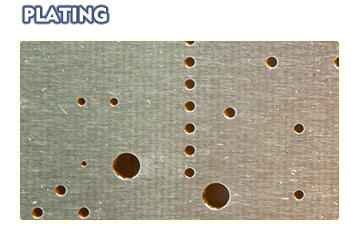

Full board plating with copper to let all apertures do copper conduction process.

Desmear => Chemical copper => Copper plating |

|

|

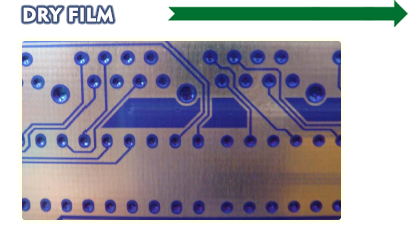

Outer image transfer using film for printing process

Photoresist (dry film) => Exposure => Developer |

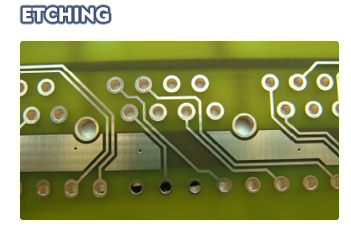

Image that finished etching and transferring,

using copper chloride to

bite the exposed copper,

allowing the blue photoresist to

remain on the surface of the board.

Etching => Removing the film |

|

|

Solder mask printing surface and filling designated via to make its circuit insulation anti-oxidation process

Ink Printing => Exposure => Development => Baking |

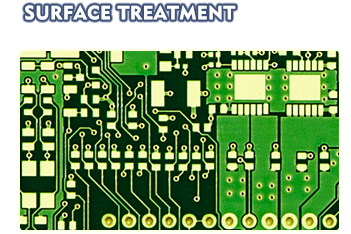

Electroless Nickel/Immersion Gold(ENIG) treatment uses

the principle

of dip-plating and transposition so that it does

not cover the area

of the bare copper surface

to form a metal cladding.

Process dip palladium => nickel dip => dipping gold |

|

|

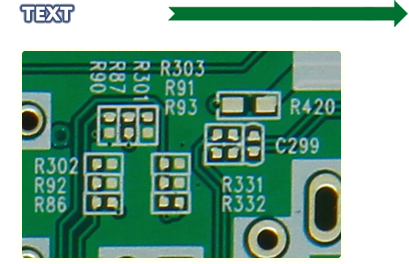

| Text using ink printed font |

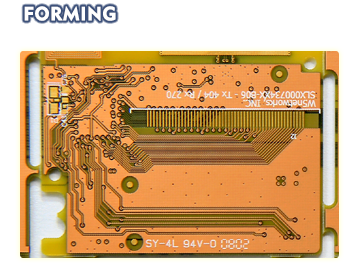

CNC type mechanical forming frame and inner tank, using V-cut on the panelization. |

|

|

Circuit Test Confirms Functionality of Wire and VIA

(100% test) |

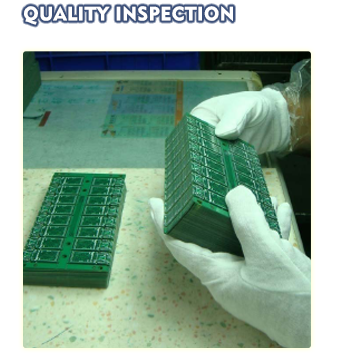

Visual inspection confirms that the material is in compliance

with the standard specification

(100% inspection) |